Aspirespace Rocket Engineering Society

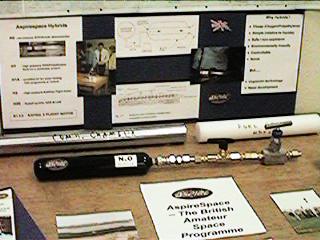

The H2 engine

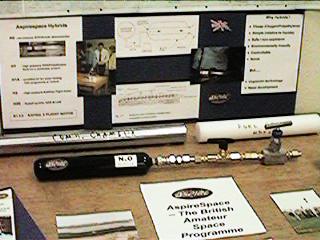

The H2 is the first Aspirespace hybrid rocket engine designed for use in a launch vehicle and the first to generate any appreciable thrust. It uses high-density polyethylene (HDPE) and nitrous oxide as its propellants and is designed to generate up to 600 Newtons of thrust from a nominal propellant mass of about 2 kg. Total Impulse for the H2 when using a 1 litre nitrous tank is around 1500 Newton-seconds, making it a mid-range 'K' class motor in High-powered Rocketry parlance. This engine was completed in 1998 and testing began in May of that year.

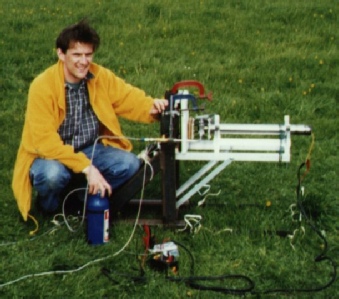

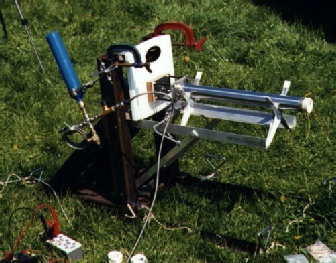

The H2 consists of an aluminium combustion chamber, approximately 50 mm in diameter and 500 mm in length, into which the nitrous oxide is injected through a specially manufactured injector. The nitrous oxide is stored in a separate tank and is delivered to the chamber under its own pressure through an actuated valve and a short length of flexible hose. (As an example of practical improvisation, the valve actuator is a modified windscreen wiper motor!)

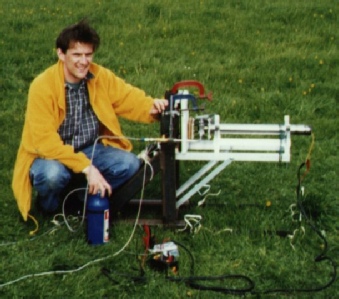

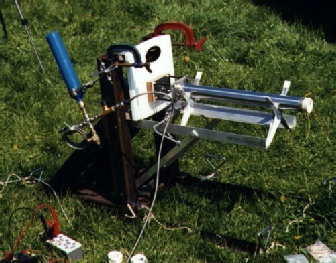

For static test firing, the chamber and oxidiser feed system are mounted on a purpose-built test stand, which is secured firmly to the ground. Pressure sensors are attached to the engine in order to record the tank and chamber pressures and a load cell is placed between the chamber and the stand to measure the thrust (further improvisation, this time using electronic bathroom scales).

Since 1998, the H2 has been successfully fired on several dozen occasions, providing Aspirespace with much needed data on hybrid combustion. Following several design modifications, a lightweight version of this engine and its nitrous tank has now been developed and is used to power the ADV2 vehicles.

To the right is a video that shows a practice firing of the H2 engine. (Double-click on the picture):