Aspirespace Rocket Engineering Society

Transform

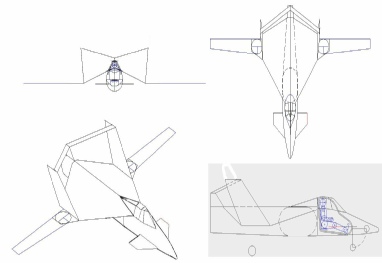

Transform is the newest member of our fleet, and the most technically complex. With Britain about to get at least one spaceport, we felt it was time we joined the club of space tourism spaceplane designers; Transform is a one-person craft that takes off from a runway and ascends into space and then flies home again to a runway. Arocket ascent and re-entry is automated (autopilot) the pilot only takes the controls for takeoff and jet climb-out, as well as after re-entry.

Of course, without the help of a beneficent millionaire, we’re unlikely to get beyond the radio controlled model stage, but it’s an interesting intellectual exercise nonetheless!

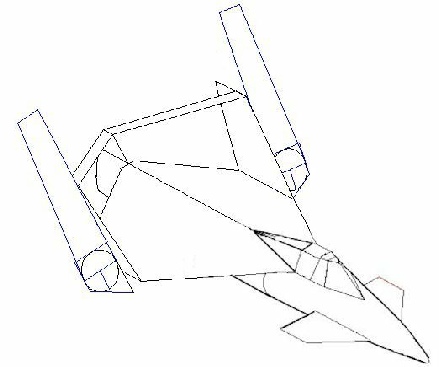

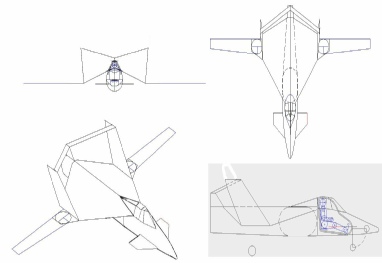

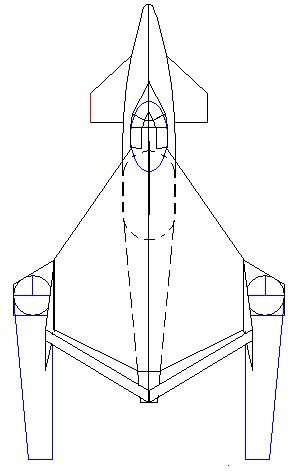

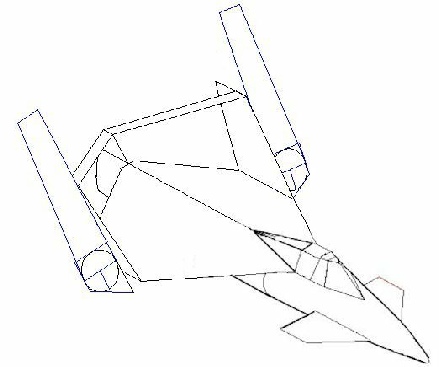

Transform is a ‘transformer’; it uses variable geometry to transition between different flight phases.

Phase 2 is a vertically ascending rocket-powered configuration, using a Lox hybrid rocket engine like our H20, but larger. We throttle back the engine to maintain a subsonic climb at Mach 0.85 until enough altitude has accrued to safely punch through the drag pulse of the sound barrier at high altitude where the air is thin.

The wings are swept back at 30 degrees to remain subcritical (reduces drag) during the Mach 0.85 ascent.

Transform is inspired by Bristol Spaceplanes’ Microsonic, Scaled Composites’ Spaceship Two, and Barnes Wallis’ Swallow.

As Spaceship Two has shown, computational stress analysis and composite wing construction allows modern variable geometry aircraft to be much less heavy than last century’s predecessors.

All the variable geometry movement is accomplished using non-reversible electric servomotors driven by lightweight ‘Li-Po’ batteries.

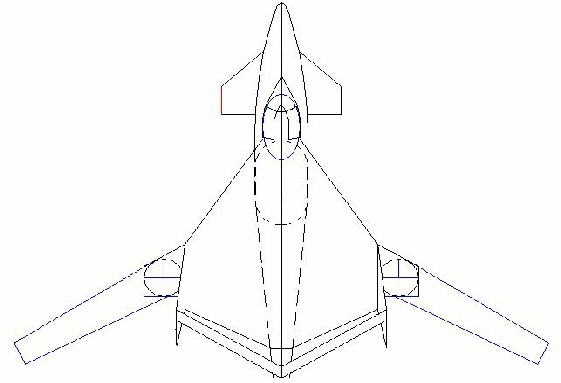

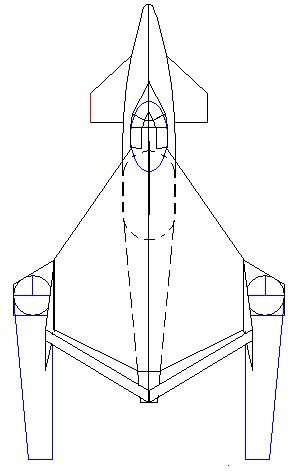

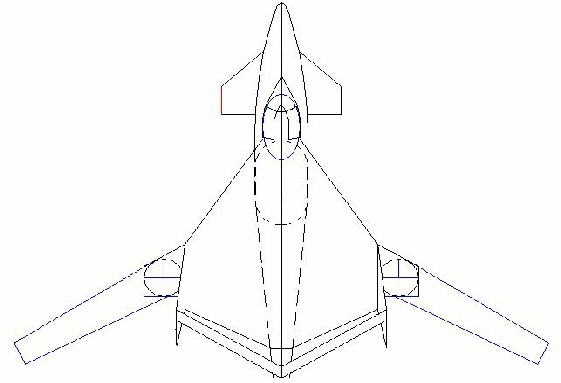

The wingtip tail-fins are spayed-out at 6 degrees off the vertical to provide re-entry ‘sidewall’ roll stability.

Transform incorporates a microjet/very light jet engine that is small but powerful, such as the Pratt and Whitney 165F (mass: 140 kg, thrust: 6 kN) but jets have to be cosseted in space or their oil will outgas and the jet won’t re-start after re-entry. So the jet has to be buried in an airtight/heatproof compartment in the rear fuselage. You also have to vibrationally isolate the jet from the rough vibrations of a rocket firing or you’ll break the jet’s bearings.

Why a windshield made from flat panels of glass? It turns out that curved panels of heatproof glass are absurdly expensive. There is a second inner cabin window for pressure backup, which is curved pre-stressed PET plastic like a soft drinks bottle: surprising strength for its light weight, but not heat-proof.

Stats:

Empty mass: 965 kg, propellant mass: 1146 kg (= mass ratio of 2.2 for a delta V of 2.47 Km/s)

Re-entry planform loading: 80 kg/m2 ( = ballistic coefficient of 88 kg/m2 gives 5.3 gees re-entry peak deceleration)

Apogee: 120 Km

Range: as required, depends on installed jet fuel tank or ferry tank.

Pitch control: all-moving canard. Roll control: inboard flaperons.

Phase 3: we throttle up and begin the rocket ascent in earnest, reaching around Mach 3.5 and four gees acceleration as the rocket burns out. The wings are fully swept back to reduce drag and to prevent overstressing them.

Phase 4: after an apogee of around 120 kilometres, the vehicle transforms into a waverider configuration for an auto-stable re-entry. The wings are now pivoted up at 60 degrees (using a separate pivot) to act as ‘Rutan feathers’ in conjunction with the tall wingtip tail-fins. (For a description of how Rutan feathers work see section 12 of our ‘Winged rockets and boost gliders’ paper downloadable in our technical papers page.)

The rear strut may seem odd on a supersonic aeroplane, but it’s carbon-fibre and very thin (low drag). It’s needed to support the tall height of the wingtip tail-fins. The strut is located so that shockwaves coming off the the wing and strut don’t interfere with each other, as this would cause hotspots.

After re-entry the vehicle transforms back into a subsonic configuration (phase 1 again) and flies back to a runway under jet power.

Phase 1 is a subsonic climb under electrically-augmented jet power at high lift-to-drag ratio (wings splayed fully out) to around 70,000 feet: